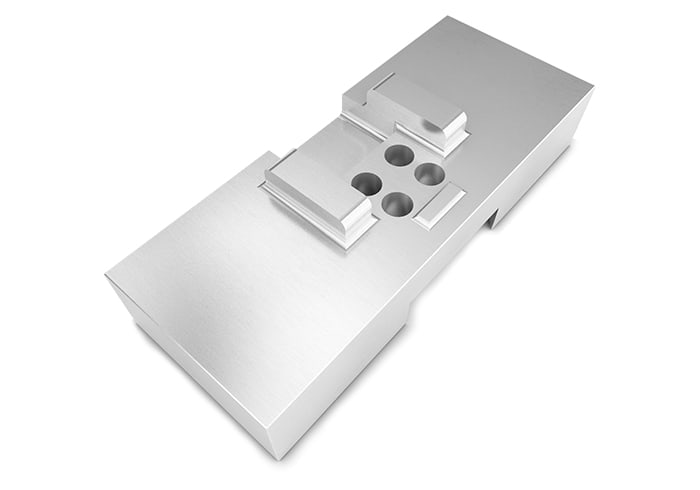

Our processing technology

In addition to standard NC lathes and machining centers, we also carry specialized equipment such as multi-spindle automatic lathes, gun drills and honing machines.

By skillfully combining the features of this standard and specialized equipment, we can create complicated unique products in-house.Our original production management system helps us closely control production processes and product delivery and provides for

efficient and exact processing of parts.

Micromachining