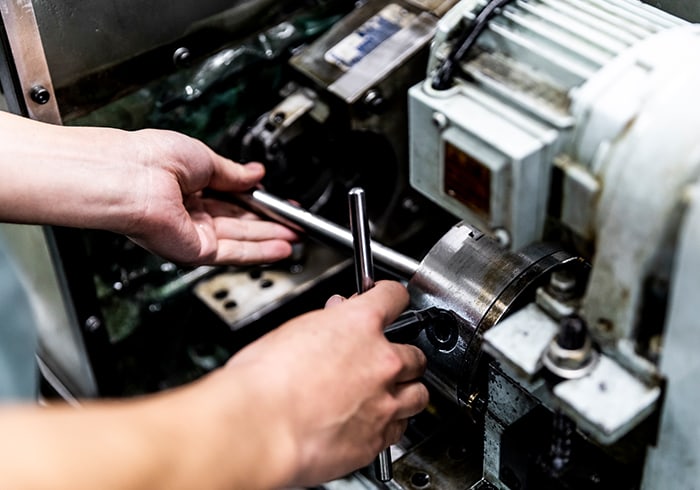

Dainichi's Precision Microfabrication

We, at Dainichi, can drill holes as small as φ 0.01 mm. As products become smaller, so do the holes used on them. The average hair is estimated to be between φ 0.08 mm and φ 0.12 mm thick, so you can understand how remarkable it is to create a hole this size.

There may not be overwhelming demand for such holes, but there are cases where we are asked to intentionally insert microscopic holes or grooves into a product to inspect how the strength and performance of a consumer good on the market is affected by minute cracks and scratches.

We also commonly drill holes of φ 0.05 mm or φ 0.10 mm in diameter as well as process microscopic holes for nozzles and other items. We have introduced ultra-precision machining centers and are skilled at drilling ultramicroscopic holes that control for tolerance at the submicron level.